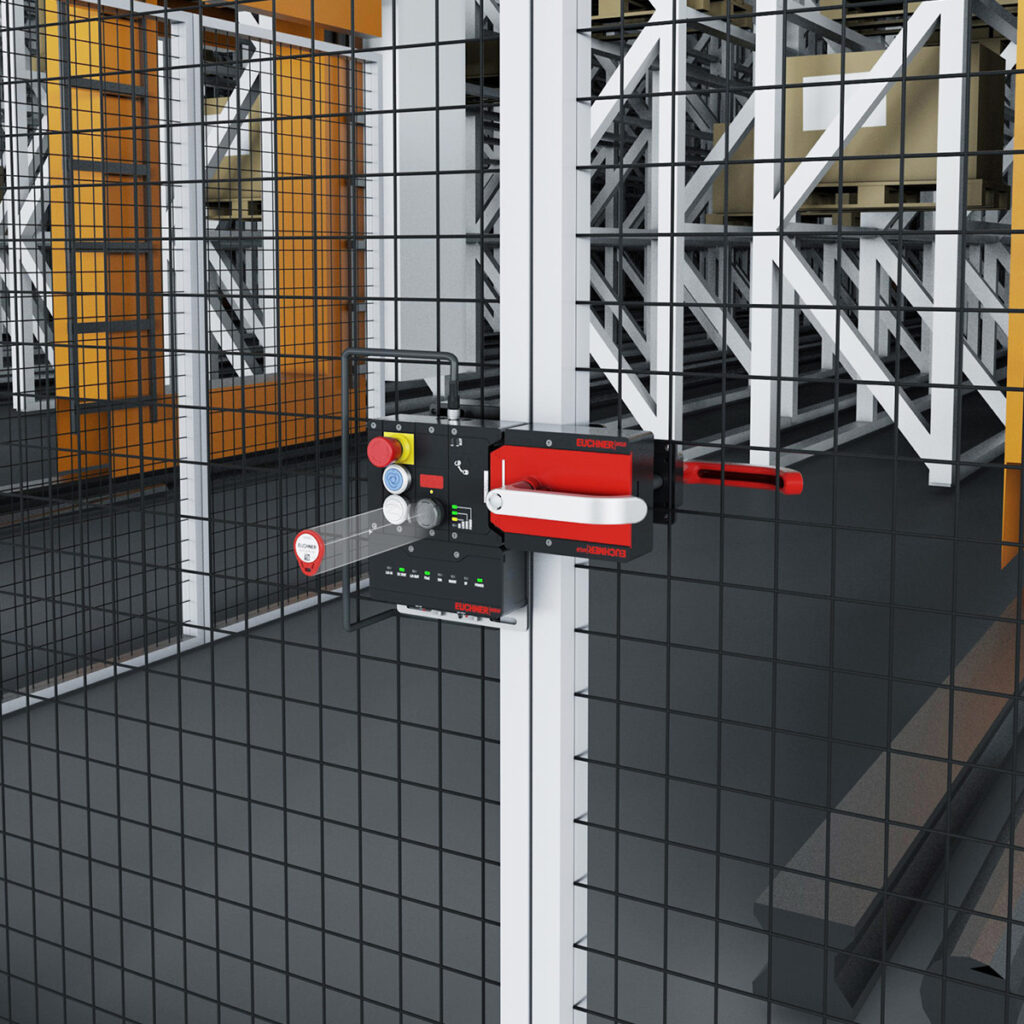

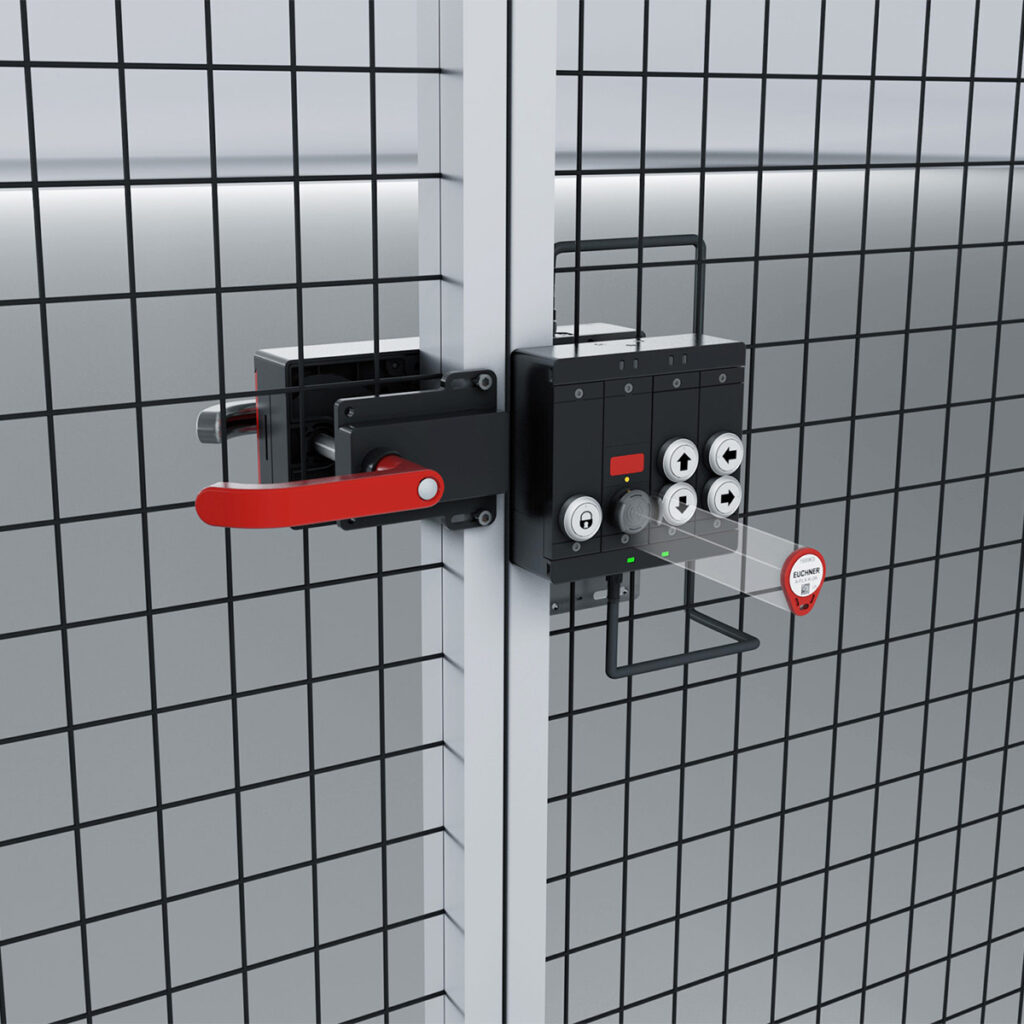

In combination with highly coded, transponder-based keys, the key adapter CKS2 forms a safe system that meets the highest safety requirements for machine and installation lockout and starting. Thanks to the integrated evaluation electronics, the compact CKS2 system can solve many tasks for you. The CKS2 system can be integrated into installations with the highest safety requirements, such as category 4 / PL e according to EN ISO 13849-1. CKS2 can be used in an installation either individually as a compact system with integrated evaluation electronics or separately as a submodule in the MGB2 Modular door locking system.

CKS2 key adapter – How it works?

Keys are taught-in directly on the key adapter, without complex programming. When the key is inserted into the key adapter, the data on the key are read and checked for validity. If the key is recognized as valid, the safety outputs switch.

The CKS2 system can be flexibly adapted to application specific requirements. As a lockout system, key transfer system or authorization system, the CKS2 system is the right choice wherever dangerous machine movements must be safely started or stopped independently of the existing safeguards.

CKS2 MSM can be linked to PROFINET / PROFIsafe or EtherCAT / EtherCAT FSoE using the bus module MBM.

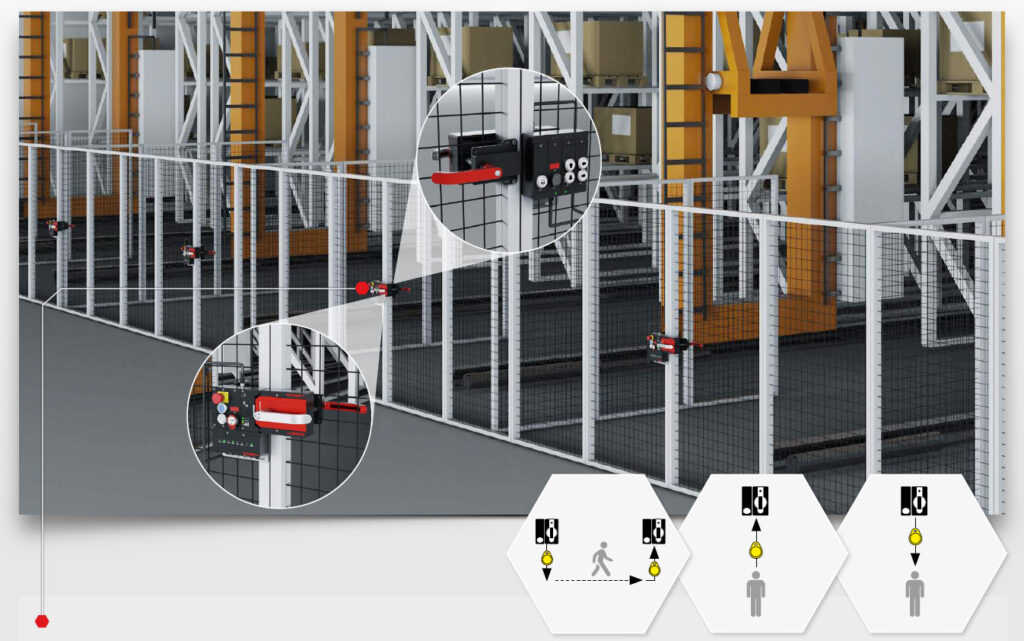

Application example: Maintenance operation of automatic warehouse

The safety door of each transport aisle is secured by a guard locking device MGB2 Modular with MSM-CKS2. No key is inserted during automatic operation.

- To stop the installation in the respective aisle, the assigned key is inserted, and a pushbutton is pressed.

- They key is withdrawn, and the door can be opened to access the aisle.

- After the aisle is accessed, the door is closed from the inside. The same key is inserted into a second key adapter in the interior. Pressing a pushbutton on an extension module MCM controls the guard locking of the safety switch.

- The automatic storage and retrieval equipment can now be controlled manually using additional pushbuttons or a hand-held pendant station.

- The key is withdrawn when the automatic storage and retrieval equipment reaches the correct position. The automatic storage and retrieval equipment is safely stopped. Work can be performed inside.

- To leave the aisle, the key is inserted into the inner key adapter on the door. The door is opened using a pushbutton.

- The key is withdrawn, and the aisle is left.

- The safety door is closed from the outside. The key is inserted. Guard locking is controlled via a pushbutton. The safety door is locked, and the installation can be started. The key is withdrawn again to continue automatic operation.

The CKS2 system can be flexibly adapted to application-specific needs. It can be used as a Lockout–tagout system, for identifying user permissions, selecting the device’s operating mode, or as a key transfer system.

The design of the safety system begins with reviewing the maintenance sequence and the area’s layout to be protected. Carefully defined and the correct placement of the system components are important to achieve the most cost-effective and easy-to-use maintenance process. If the design of your safety system is relevant to you, don’t hesitate to contact us. We will be happy to help you with the design and take a step towards future-proof safety systems.

Sähkölehto x Euchner partnership for 30 years

Sähkölehto offers expert solutions and products for industrial machine safety. Co-operation for the past 30 years has forged a strong and enduring partnership with Euchner, we are proudly working as their official partner in Finland and the Baltic countries. Our trained experts are always pleased to help in choosing the right solution, from the beginning of the design to system implementation to production. We have solid know-how and a wide range of products in the field of machine safety. We can offer a safe, reliable, long-term solution for your company’s needs. Our operations are based on partnership and reliability, which means our commitment to offer our customers high-quality customer service and support well into the future.

Euchner Safety Solutions

As specialists in industrial safety engineering, Euchner develops and manufactures products and solutions tailored to the requirements of customers from a wide range of sectors. Euchner’s guards on machines and installations minimize hazards and risks, which in turn protects people and processes. Euchner’s own quality standards go beyond those stipulated by standards and laws, but their aspirations are higher still. Euchner manufactures all central components in-house on the latest machinery. Euchner’s internal quality management processes ensure that no product leaves the premises without detailed inspection.

Did you find this content interesting?

Stay updated with the latest articles by following Sähkölehto on LinkedIn