MGB2 Modular is the world’s first guard locking device for the safe EtherCAT

2009

In 2009, Euchner developed the first safety door system incorporating PROFINET/PROFIsafe and thereby established an entirely new category of safety door systems with an integrated safe bus connection.

2014

A few years later, in 2014, Euchner was the first company to market a safety door system using integrated EtherNet/IP with CIP Safety.

2018

The market for safety door systems with safe bus connections began to grow, as the advantages of the industrial safe bus systems were more widely recognized and appreciated. Based on customer feedback, in 2018 Euchner introduced the completely renewed MGB2 Modular safety door system for the PROFINET/PROFIsafe interface. Euchner has always remained true to the basic MGB2 principle of modularity and simple integration. Users can customize their guard protection and machine controls with a modern and enhanced MGB2 Modular system.

The new generation safety door system is more versatile and cost-effective which has led to its use in various industrial sectors, guard locking different dangerous production lines and machines.

2021

In 2021, Euchner expanded its range again by developing the MGB2 Modular series for EtherCAT and EtherCAT/P interface. The integration of the products into the EtherCAT / FSoE (FailSafe over EtherCAT) is a significant development step, as the MGB2 Modular is the world’s first guard locking device for the safe EtherCAT.

MGB2 Modular – Versatile safety door system for the safe bus

The advantages of the MGB2 Modular safety door system are its modularity, simple integration, and easy connection to different safe bus systems. The modular design and the optional MSM submodules offer countless variants, additional functions, different networking options, and intelligent communication features for Industry 4.0 applications.

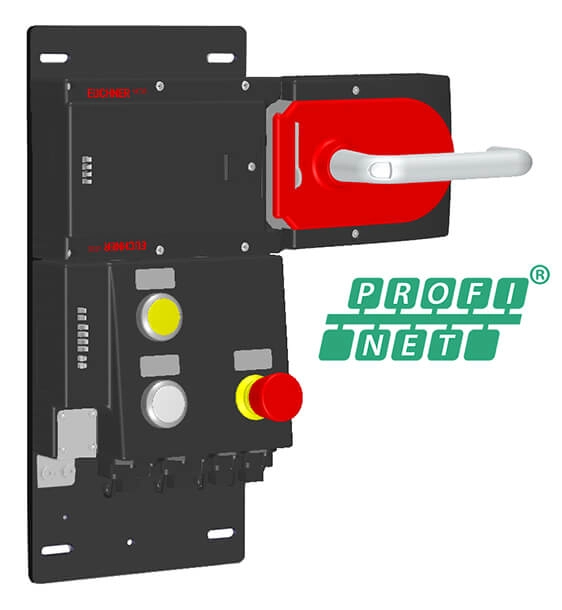

MGB2 Modular is designed to adapt to the needs of different applications. This has been achieved by dividing the main functions of the system into three different modules. The bus module communicates between the control system (PLC) and the components connected to the system. The safety switch MBG2 is guard locking and monitoring the status of the door but also enables additional controls, indicators, or an additional safety device such as an emergency stop. Expansion modules MCM enable various control functions and the connection of further safety components to the system.

The MGB2 Modular can meet individual requirements thanks to its modular system design and wide selection of modules. A solution that can be tailored to meet all the requirements is a sensible choice.

Data transfer and system control through modularity

The Euchner MBM bus module works as an interface between Euchner’s own MLI bus and the industrial safe bus of the control system. The information from the different modules is transferred to the PLC via the MBM bus module and vice versa. This signal can be used e.g. to control the locking of the safety door or to activate an indicator light of the system status.

Since the MBM factory bus module works as a bus converter, by changing the bus module, the same MGB2 Modular components can also communicate with a different safe bus. The program is stored in the memory of the MBM bus module, which works as the central component of the system.

Ever since the MGB2 Modular for PROFINET/PROFIsafe entered the market in 2018 it has been in high demand. Likewise, the safety door systems for EtherCAT/FSoE connection introduced in November 2021 are now convincing an ever-growing number of users.

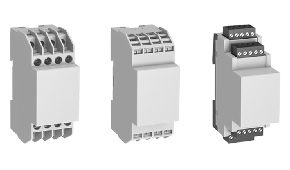

Alternative MBM bus modules enable the connection to different industrial safe bus systems.

Maximum personalization for safety door systems

No two safety applications are the same. Some production processes need an additional safety device such as an emergency stop to secure safety doors with guard locking, while others need request and acknowledgment buttons to be mounted directly onto the safety door. The MGB2 is more than just a pure safety switch. It makes it possible to integrate all functions into one device.

There is space for up to two submodules MSM. In this way, a very wide range of control elements from emergency stops, through pushbuttons, to key-operated rotary switches can be added such that a complete control terminal can be created on the door. A wide selection of submodules and the connectivity of other safety components enable countless alternative controls. In addition to the control functions, the illuminated buttons also provide clear information about the state of the protected process or robot cell.

Due to the modular design, the MGB2 Modular switch can be easily mounted on both left and right-hinged doors. MGB2 is also suitable for both hinged and sliding doors. It’s also possible that, over time, new requirements may arise for safety door systems because of conversions or expansions to machines, installations, and production lines. The MGB2 safety switch can be easily modified according to these changes.

The various control functions of the device to be protected can be implemented with interchangeable button modules in the MGB2 Modular safety lock.

More control functions

If more functions are needed for the system, the MCM expansion module increases the capacity for up to four button modules. This enables the creation of a separate control panel for the MGB2 Modular system. A wide selection of different submodules allows the creation of an optimal application-specific control system. In addition, the button module is available with additional safety inputs, which enables separate electromechanical safety limits, RFID-coded safety limits, and Emergency Stop buttons to be connected to the safe bus.

MCM expansion module allows the connection of the electronic key system CKS2. It can be used as an electronic logout tagout system, to identify the user access rights, to select the operating mode of the device, or as a transfer key system.

MCM Modular expansion modules can be used as a separate control panel. Separate enabling switches, electromechanical and RFID-coded safety switches, and E-stop buttons can be connected to M12 connectors.

System overview:

Bus module MBM

- Gateway between all MGB2 locking modules, MCM extension modules, MSM submodules, and the control system (PLC) via various industrial networks.

MGB2 Modular security lock (locking module + handle module)

- Modular door-locking systems

- For doors hinged on the right or left

- For hinged or sliding doors

- Space for two MSM submodules

MCM Modular expansion modules

- Space for two or four MSM submodules

- Direct control of a stack light

MSM button modules

- Modules with up to three controls and indicators

- Control buttons, rotary switches, safe acknowledgment buttons, LED indicators, emergency stop switches, and many other functions.

- Also, additional electromechanical and RFID-coded safety switches can be connected via M12 submodules.

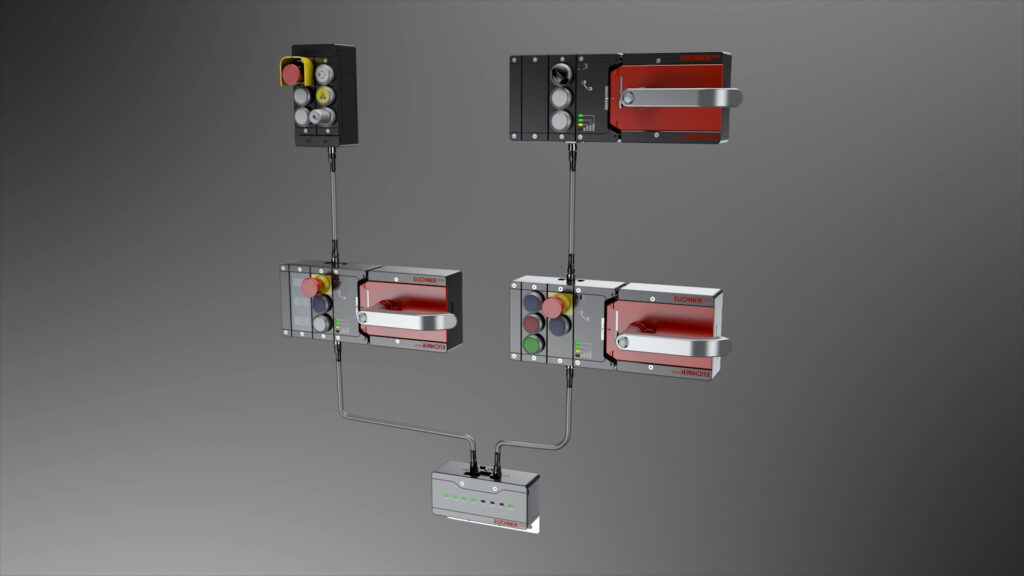

Fewer components, more intelligence – Up to six service doors connected to one bus module

Up to six MGB2 Modular security locks or MCM expansion units can be connected to one bus module. Since the communication of the MGB2 Modular system only takes place via one bus module, fewer address spaces and interfaces are also needed on the control system side. This saves on the storage capacity of the control system, which also becomes more and more expensive in future factories with more and more intelligent systems.

The separate bus module of the security system creates more space for the door. The dispersed placement of the components also enables the bus module to be installed in a switch cabinet or in a central location, for example between service doors. Scattered placement, especially in tight spaces, enables flexible installation of the system.

Euchner MGB2 Modular – Application example

MGB2 Modular EtherCAT / EtherCAT P – System overview

A well-known and reliable solution

Euchner MGB2 safety locks have a well-established reputation in the automotive industry and in various areas of the automation industry. Users have been able to enjoy a flawlessly functioning door locking system, which covers the requirements of the highest PL e level according to EN ISO 13849-1, but also easily adapts to the requirements of future applications. When planning the device, you want to end up with a solution that is versatile, high-quality and long-lasting, the MGB2 Modular system is certainly a reasonable investment.

The design of the MGB2 Modular system often begins with reviewing the floor plan of the area to be protected. Carefully defined system components and the correct placement of components are important in order to achieve the most cost-effective package and an uncomplicated maintenance process for the device. If the design of the MGB2 Modular system is relevant to you, contact us and we will be happy to help you with the design and to take a step towards the systems of the future.

Sähkölehto x Euchner partnership for 30 years

Sähkölehto offers expert solutions and products for industrial machine safety. We have acted as Euchner’s official sole representative in Finland for 30 years. Our experts are always involved in choosing the right solution, from the beginning of the design to system implementation and production. We have solid know-how and a wide range of products in the field of machine safety. We can offer a safe, reliable and long-term solution for your company’s needs. Our operations are based on partnership and reliability, which means our commitment to offer our customers high-quality customer service and support well into the future.

Euchner Safety Solutions

Euchner’s guards on machines and installations help to minimize hazards and risks to people and production processes.

Special expertise in industrial safety technology allows Euchner to design and produce customized solutions and products for customers in different industries. Customers are not just buyers, but important partners whose collaboration helps develop the best solutions.

Euchner’s quality standards exceed those set by regulations and laws. All key components are manufactured in-house, and internal quality control ensures that every product leaving the factory has gone through a quality check.

Did you find this content interesting?

Stay updated with the latest articles by following Sähkölehto on LinkedIn