Hygiene and resilience for medical technology

Medical technology applications demand strict hygienic and mechanical standards. To address these needs, ODU has created a series of silicone-overmolded system solutions. These solutions feature non-sticky surfaces and are designed for easy cleaning, steam sterilization, flexibility, resistance to extreme temperatures, and have been tested in accordance with DIN EN ISO 10993-5. This ensures they provide a hygienic and durable solution for everyday medical use.

To meet specific medical requirements, ODU offers customized silicone-overmolded system solutions that include connectors, overmolded components, and cables, along with assembly and optional laser marking.

ODU offers you

- Connectors with silicone overmolding and cable assembly

- Carefully matched materials for optimal haptics, hygiene, and durability

- Partnerships with leading cable manufacturers

- Take care of testing, documentation, and certification for you

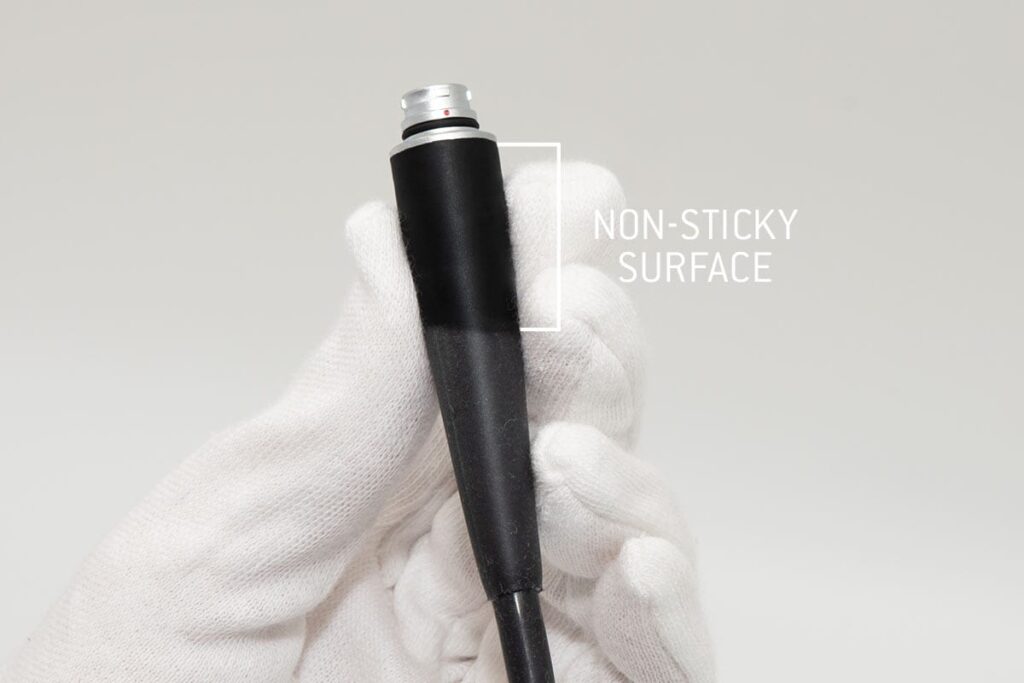

Avoiding the stick‐slip effect

The specially developed surface of the cable and overmolding has a pleasant feel and prevents stickiness and the stick‐slip effect, even after continuous use. In combination with the smooth transitions to the overmoldings, the non‐sticky surface makes the cables extremely easy to clean – and thus ensures maximum hygiene for medical applications.

- Hygienic cable assembly including overmolding

- Pleasant, non‐sticky feel without the stick‐slip effect

- Certified in accordance with ISO 10993-5

Steam sterilization in autoclave

Hygiene as a benchmark for the medical industry: ODU silicone‐overmolded system solutions are permanently compatible with both manual and mechanical cleaning methods. Even more important, however, is their thermal stability during steam sterilization – for up to 500 autoclave cycles. The surface properties remain unchanged, permanently.

New shape for maximum kink protection

A particularly important feature of our silicone‐overmolded system solutions is the kink protection, which is provided by means of a sliding overmolding. This guarantees high bending fatigue strength for the cable and overmolding, while eliminating any edges which could potentially harbor unhygienic contaminants. The adhesion between the cable jacket and the overmolding remains durable even after steam sterilization and extreme stresses.

Other reasons

Why silicone‐overmolded system solutions are ideal for use in the field of medical technology:

- Maximum bending fatigue strength

- Tested for medical technology use

- Recognized LSR and HCR processes are available globally

- Individual laser marking possible

- Various standard inserts available

- Very good mechanical properties

- Customized contact configuration

Key application areas for silicone‐overmolded system solutions

ODU products are used in diverse areas ranging from endoscopy to dental medicine

Endoscopy

Endoscopy is one of the most important application areas for our silicone-overmolded system solutions. The use of highly flexible and autoclavable, skin-friendly, and slippery materials is of particular importance here.

- For high‐resolution images in the ultra‐high vacuum range

- Gentle on the skin and slides well

- Steam sterilizable

- Smallest possible outside diameter depending on defined number of contacts

Monitoring

Monitoring systems that measure brain waves, oxygen, blood pressure, or body temperature require soft, flexible, and hygienic connectors with a high number of mating cycles. Silicone‐molded solutions can also withstand mechanical influences and are fail‐safe when transporting the respective devices. This ensures continuous monitoring of the patient.

- For use with ECG, measurement of oxygen, blood pressure and temperature

- Fail‐safe and vibration‐resistant even during transport of the devices

- Resistant to mechanical influences such as torsion, vibration, and bending

- Can be disinfected by wiping, steam sterilizable

Robotics

In the field of robot‐assisted surgical aids, the cable connections are exposed to varying loads such as tension or torsion. In this case, silicone‐overmolded system solutions offer optimum mechanical robustness and thus failure protection and reliability – while also meeting the strictest hygiene standards.

- For use under a wide range of loads

- Reliable even when subjected to tension or torsion

- Cables and connections can be combined as required by the customer

Dental

Many applications in the field of dental equipment require hybrid connections with a parallel supply of water, electricity, air, or light. Silicone‐overmolded system solutions are suitable for a wide range of hybrid connections and allow easy‐to‐clean cable assemblies thanks to their non‐sticky surface.

- Hybrid connections available for parallel supply of water, air, and electricity

- Sterilizable

- Surface without stick‐slip effect

Sähkölehto x ODU

The best connector solution achieved through collaboration

Sähkölehto has long experience with connectors, various connection solutions, and Finnish industry. We work closely with our long-term partner, ODU GmbH & Co. KG. The solutions we provide are known for their reliable, interference-free connections and often long contact life – from thousands to even a million connection cycles.

It’s worth investing in the evaluation of connector solutions because the connector must guarantee reliable performance in its application and be economically sensible. This is not just a technical aspect; it is equally important to choose a reliable supplier who ensures the availability of the selected connector solution in the future.

Summary

ODU cable assemblies for medical technology

- New surface with unique haptics – no stick-slip effect

- Up to 500 autoclave cycles

- Bend protection thanks to special shape of overmolding

- Approved LSR and HTV processes globally available

- Maximum alternating bending strength

- Tested for medical technology use

- Individual laser labeling possible

- Various standard inserts available

- Optimal mechanical properties

- Customized contact configuration

- Halogen- and latex-free

ODU GmbH & Co. KG

ODU is a German company and one of the leading connector manufacturers globally. Headquartered in Mühldorf and founded in 1942, the company specializes in developing high-quality, reliable connectors. ODU’s product range includes circular connectors, modular connector systems, and customized solutions used globally in medical, military, and test and measurement equipment. ODU’s innovations and commitment to meeting customer needs make it a trusted partner in even the most demanding applications.

Did you find this content interesting?

Stay updated with the latest articles by following Sähkölehto on LinkedIn: